Over 30 years of experience in engineering management consulting and ASME Codes and Standards.

Welcome to Reedy Engineering

Reedy Engineering is an engineering consulting firm located in Campbell, California. With over 30 years of experience in engineering management consulting and ASME codes and standards, we have continuously helped our clients to reduce the costs associated with design, construction, repair, replacement and modification of pressure retaining equipment. We also seek to assist our clients in their understanding of ASME code requirements for maintaining quality and safety, without sacrificing time and financial resources. Our goal is to educate our clientele and teach them how to resolve ASME boiler and Pressure Vessel Code, and other regulatory issues. At Reedy Engineering, we specialize in a variety of consulting services including:

- ASME Codes and Standards (specifically in the area of application for design, fabrication, NDE, inspection and quality assurance)

- Boilers and Pressure Valves

- Piping

- Valves

- Structures and Supports

- Welding (ASME and AWS evaluations)

- In-Service Inspection Issues

- Quality Assurance and Control

- Design Evaluations and Specifications

- Code Compliance

- Repairs and Replacements

Consulting for the above areas is provided on an hourly basis. We also offer the option for a Retainer Agreement (inexpensive telephone consulting with incorporated billing rates and unlimited use of a computer database of various code interpretations). Our teams of engineers are always available to assist customers with technical support and approach each question and challenge from a solutions-driven standpoint. It is our expertise in this field and attention to detail that sets our company apart. As engineering consultants on a variety of projects, some generated reports can occasionally be used effectively by a number of clients. We present four different reports:

- ASME Code Reconciliation (allowing nuclear power plant clients to know whether a material can be used without affecting the design of an item. These reports can be generated within a few minutes).

- RA-Search Database (permits clients to find any ASME Interpretation within seconds).

- Underthickness Report (permits a client to evaluate and temporarily accept an area of a pressure vessel or piping system that has been corroded, eroded, or otherwise reduced in thickness).

- NDE Report (allowing a client to easily upgrade material from one Class to another). Reedy Engineering is proud to offer clients a training course and a seminar to further education on ASME code requirements and philosophy. The training course is titled, "ASME Section XI" and covers these areas of learning:

- Repair, Replacement, Modification and Maintenance

- Pressure Testing

- Code Relationship with Regulatory and Enforcement Requirements

The seminar provided by Reedy Engineering is titled, "Using ASME Codes and Standards to Reduce Plant Operating Costs". The seminar objectives are to properly use ASME codes and Standards to eliminate unnecessary engineering and repair/replacement activities. This course will highlight these issues and accent the necessity of engineering judgment when approaching challenges in this regard.

When challenges do arise, Reedy Engineering is prepared with experts and consultants for testifying on ASME Code issues regarding general requirements, materials, design, fabrication, nondestructive examination, and testing for quality assurance. We have participated as principle experts in lawsuits regarding petrochemical plants, subway systems and nuclear power plants, among others. Please contact us at 408-558-0330 or ras@reedyeng.com so we can determine how to best serve you with your engineering and consulting needs.

ABOUT US

A top engineering consulting firm since 1981, we have helped clients understand and implement ASME Code requirements for design and construction of pressure retaining components. We have continuously helped our clients to reduce costs associated with design, construction, repair, replacement, and modification of pressure retaining equipment.

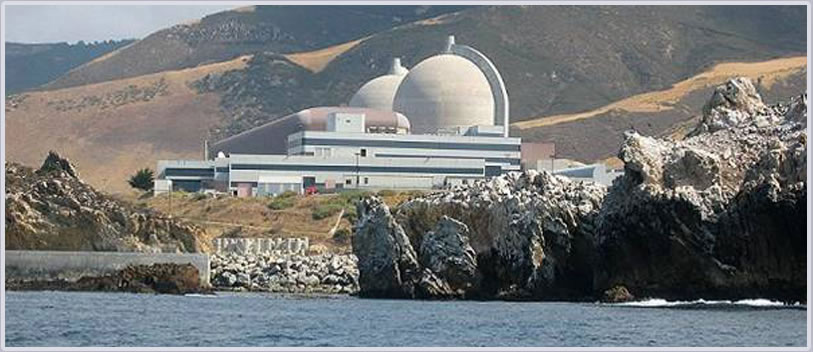

Reedy Engineering has consulted for most of the nuclear utilities in the United States and Canada, as well as several in Europe and Asia. We are often involved in helping our clients resolve licensing issues with the USNRC and other international regulatory bodies.

ASME CODE CONSULTING

When we act as ASME Code Consultants, our goal is to help our clients maintain quality and safety, without sacrificing time and money. We teach our clients to resolve ASME Boiler and Pressure Vessel Code and regulatory issues for themselves. We provide training in ASME nuclear construction and inservice inspection requirements and in support of ASME accreditation.

EXPERT TESTIMONY

Reedy Engineering is often hired to provide expert witness services in complicated litigations involving design, construction, materials, welding, and quality issues, due to our long involvement in ASME Codes and Standards activities. We have successfully defended many companies against asbestos litigation.

NEWS

Our RA-Search database has been updated to include all the latest published ASME Code Interpretations for 2012. The database also includes comments on every change to the ASME Boiler and Pressure Vessel Code and the ASME B31.1 and B31.3 Piping Codes from 1952 to 2012. Comments on all of the ASME Code changes in this period are not available from any other source.

The Reedy Engineering Code Reconciliation Report has been updated to include the changes in the 2011a Addenda to the ASME Boiler and Pressure Vessel Code. It is currently being used by more than 30 nuclear utilities in the United States and Europe.